Motors

Motors are one of the most important parts of an FPV drone — they convert battery power into mechanical force to spin the propellers and make flight possible. FPV builds use brushless motors for their high efficiency, precise control and long service life (no carbon brushes). Simple brushed DC motors appear only on some budget tinywhoops.

Motor construction

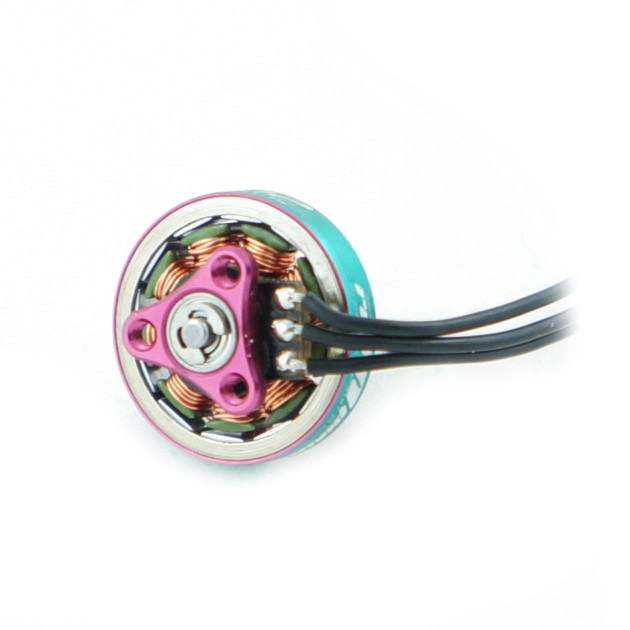

A brushless motor consists of two main parts — the stator and the rotor. The stator is the fixed part mounted to the frame. It carries windings (electromagnets) on a steel core made of thin laminations to improve magnetic efficiency. The winding wire is copper with heat-resistant insulation up to 180 °C. The stator also houses the bearings.

The rotor (the bell) is the moving part with neodymium permanent magnets and the shaft. The bell is typically made from strong aluminium alloys for low weight and good heat dissipation. The motor shaft is hardened steel or titanium alloy to save weight. It is retained in the stator by a circlip on the bottom of the motor, or by a small M2–M3 screw fixing the rotor. This prevents the rotor from pulling out in crashes or rapid throttle changes.

High-quality motors use precision bearings (e.g., NSK, NMB, EZO), lightweight 7075 aluminium bells, titanium shafts and curved N52H magnets to minimise the air gap between stator and rotor. The result is lower losses, faster response and higher efficiency.

Motor size notation

Motors are labelled with four digits such as 2306 or 2207. The first two indicate the stator diameter in millimetres, the last two the stator height. Stator size determines the stator volume (copper + magnetic field) the motor can use — and thus its torque.

As a rule, the larger the stator volume (total copper/flux), the higher the torque and potential power — regardless of whether the motor is wide/low (e.g., 4108) or narrow/tall (e.g., 2817). With size you also increase weight, current draw and overall energy consumption.

Kv value

Kv is the no-load RPM per volt. For example, a 2300 Kv motor on a 4S pack (16.8 V) has a theoretical maximum of about 38 640 RPM. Higher Kv gives higher RPM but more current draw and shorter flight time; lower Kv reduces RPM but improves efficiency and extends flight time.

Matching motor, prop and battery

Choosing the right combination of motor size, Kv, propeller and battery voltage is key to the desired flight feel. Faster-spinning props need a larger, higher-torque motor to overcome aerodynamic load. Kv is always selected with respect to battery voltage so the motor hits an optimal RPM where the propeller delivers the required thrust.

The motor must sustain those prop RPMs. If you pick too high Kv or too small a stator, you can overheat the windings and damage insulation. Oversizing the motor or choosing too low Kv wastes weight and potential. Aim for a balance of performance, efficiency and mass.

The following table gives common pairings for typical FPV drones:

| Prop size | Motor size | Battery & Kv | Typical use |

|---|---|---|---|

| 31–40 mm (1.2–1.6″) | 0603 – 0802 | 1S: 19 000 – 25 000 Kv | Tinywhoop, indoor |

| 2″ | 1103 – 1106 |

2S: 11 000 – 15 000 Kv 3S: 7 000 – 10 000 Kv |

Micro freestyle, toothpick |

| 3″ | 1105 – 1404 |

3S: 5 000 – 6 000 Kv 4S: 3 800 – 4 800 Kv |

Mini quads |

| 4″ | 1404 – 2004 |

4S: 2 500 – 3 800 Kv 6S: 2 000 – 2 800 Kv |

Light freestyle, long-range |

| 5″ | 2205 – 2306 – 2207 |

4S: 2 300 – 2 600 Kv 6S: 1 700 – 2 100 Kv |

Racing & freestyle |

| 6″ | 2306 – 2506 – 2806.5 |

4S: 2 100 – 2 300 Kv 6S: 1 300 – 1 800 Kv |

Cinematic freestyle |

| 7″ | 2506 – 2806.5 – 2807 | 6S: 1 100 – 1 400 Kv | Long-range |

| 8″ | 2807 – 2814 | 6S: 1 100 – 1 300 Kv | Long-range, cine-lifter |

| 9″ | 2816 – 3115 | 6S: 900 – 1 100 Kv | Long-range, cine-lifter |

| 10″ | 3110 – 3120 | 6S: 800 – 900 Kv | Long-range, cine-lifter |

This table is an orientation guide — always verify current draw of specific motors/props via thrust tests or the manufacturer’s data.

Motor mounting hole patterns

Motors are bolted to the arms. The spacing is specified as the bolt circle diameter (BCD), not centre-to-centre. Common sizes:

- Φ 6.6 mm M1.4 — three-bolt pattern. Tinywhoop motors (0702, 0803)

- Φ 9 mm M2 — small 2–3″ motors (1103, 1105, 1404)

- Φ 12 mm M2 — smaller 3–4″ motors (1404, 1806, 2004)

- Φ 16 mm M3 — standard for 5–6″ quads (2207, 2306, 2506)

- Φ 19 mm M3 — larger long-range motors (2807, 3115)

- Φ 30 mm M4 — big motors for 13–15″ (4214, 4320, 5315)

Prop attachment types

Propellers mount differently depending on shaft diameter and bell design. Tinywhoop motors (e.g., 0703–0802) use a smooth 0.8/1/1.5 mm shaft — props push on by friction. Small motors (e.g., 1103–2004) commonly have a 1.5 mm shaft and a two-bolt T-mount (two M2 screws on 5 mm spacing). Mid/large motors (typically 1507–3120) use a threaded 5 mm shaft with a prop nut. Large motors for 13–15″ props use a 6 mm threaded shaft. Biggest industrial setups (15–20″) often bolt props with 2–4× M3 directly to the hub.

Efficiency & performance

For objective comparisons, use static thrust tests measuring thrust (g), current (A) and efficiency (g/W). These tests show how a motor behaves with different props and batteries — helping you find the optimal combo for your build.